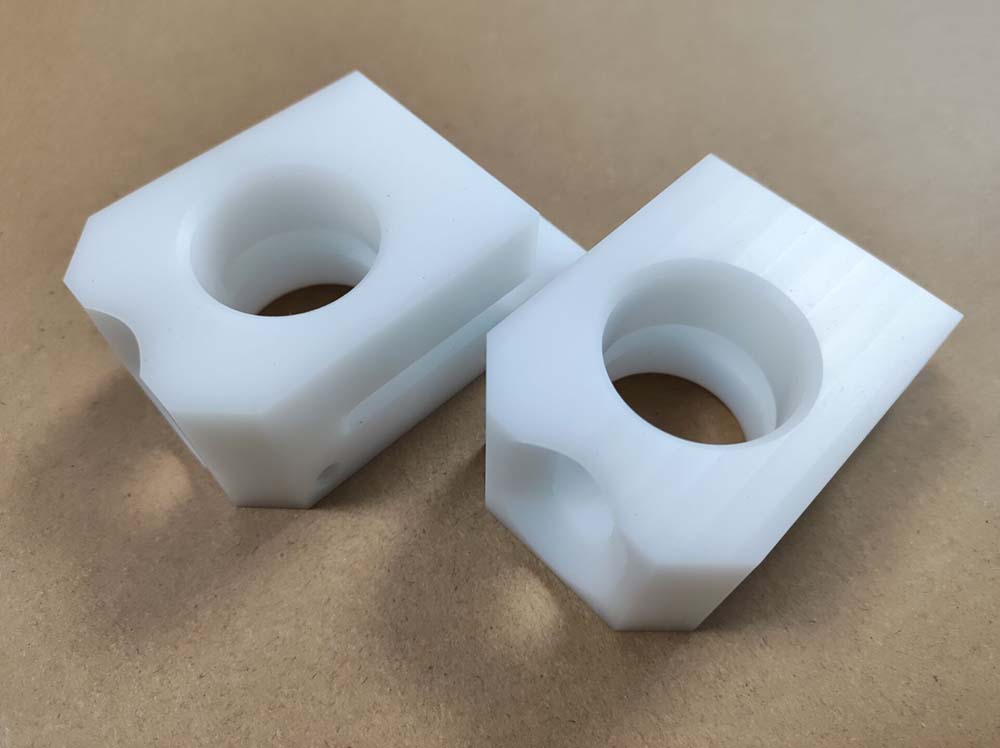

Custom HDPE CNC Machining Services

High-Density Polyethylene or HDPE is an engineering plastic that has excellent chemical resistance, electrical insulation and smooth surface. HDPE is an ideal material for making plugs, seals, boat components, piping, containers. HDPE is widely used in weight-sensitive or electricity-sensitive applications. When you need HDPE part that not coming from any 3D printing material or silicone molding materials, CNC machining is a perfect manufacturing process.

Our Strengths in CNC HDPE Machining

Professional Team, Skilled specialists

TENGHUI is a plastic machining expert with over 10 years of experience. We have manufacturing expertise in for HDPE material parts. Our skilled specialists and engineers can provide the best manufacturing solution according to the part structure, and minimize the deformation problem due to high temperature machining work.

Quality assurance

TENGHUI is always processing HDPE parts and other plastic parts according to the customer’s specifications and drawings. TENGHUI is proud of delivering premium quality product to our customers with intricate detailing, aesthetic appearance and accuracy that exceed customer specifications. we have a complete set of inspection process, well-functional measuring equipment and devices to ensure our product quality.

Benefits of Using HDPE for CNC Machining

- More accurate

CNC HDPE machining that provides precision parts with better tolerance than injection molding and 3D printing. HDPE plastic parts by CNC machining provides greater dimensional accuracy. 5-axis CNC milling machines enable high-precision machining of more complex parts. CNC Machined HDPE parts is without layering lines of 3D printers or the parting lines of injection molding. So the final parts is with aesthetic appearance.

- No need mold

Injection molding for HDPE parts is a Manufacturing methods with high cost, long designing time, long lead time and some risks. Choose CNC machining for prototyping or small batch production, the designers and engineers can manufacture HDOE parts easily and freely.

- Flexible design for parts structure

The HDPE Parts can be machined directly from plastic plate or plastic round bars. As 3-axis, 4-axis, and 5-axis CNC machines are available, most of the designed structures can be realized.

- fast turn-around time

CNC machines are computer controlled and remain operational 24 hours/day.CNC machines are working at high efficiency, optimum quality.